Services

At TPR Engineering, we offer customized industrial automation solutions that cover the entire project lifecycle, from initial conception to post-implementation maintenance. Our services are designed to optimize productivity, improve efficiency, and maximize the performance of our clients’ facilities.

- Industrial Process Automation

- Custom Engineering and Design

- Robotics and Artificial Vision

- Maintenance and Technical Support

Industrial Process Automation

We offer complete solutions for the automation of industrial processes, including the integration of advanced robotics and artificial vision systems. We focus on improving efficiency and reducing operational costs, ensuring greater flexibility and adaptability to production changes.

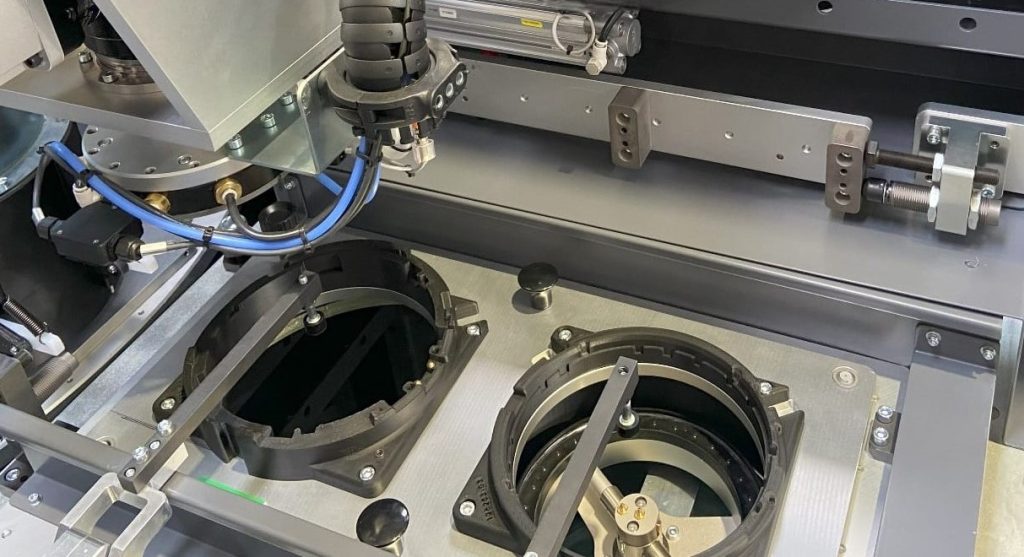

Component assembly and handling

Palletizing and packaging systems.

Automated quality control

Custom Engineering and Design

We understand that each project is unique. That is why we offer custom engineering services, working closely with our clients to develop solutions that perfectly match their specific needs. From the initial idea to the final product, we take care of all the technical details.

Design and manufacture of special machines.

Integration of control and automation systems.

Adaptation and improvement of existing production lines.

Robotics and Artificial Vision

Robotics and artificial vision are fundamental pillars of our automation solutions, allowing greater precision, speed, and efficiency in production processes. We develop custom robotic applications that significantly improve production capacity.

Vision systems for quality inspection.

Robotic cells for assembly and handling.

Automation of processes with high precision requirements.

Maintenance and Technical Support

Our commitment to clients goes beyond project implementation. We offer maintenance and technical support services to ensure that our solutions continue to operate at peak performance, minimizing downtime and optimizing equipment life.

Preventive and corrective maintenance.

Remote and on-site technical support.

Software and hardware updates.

Technologies

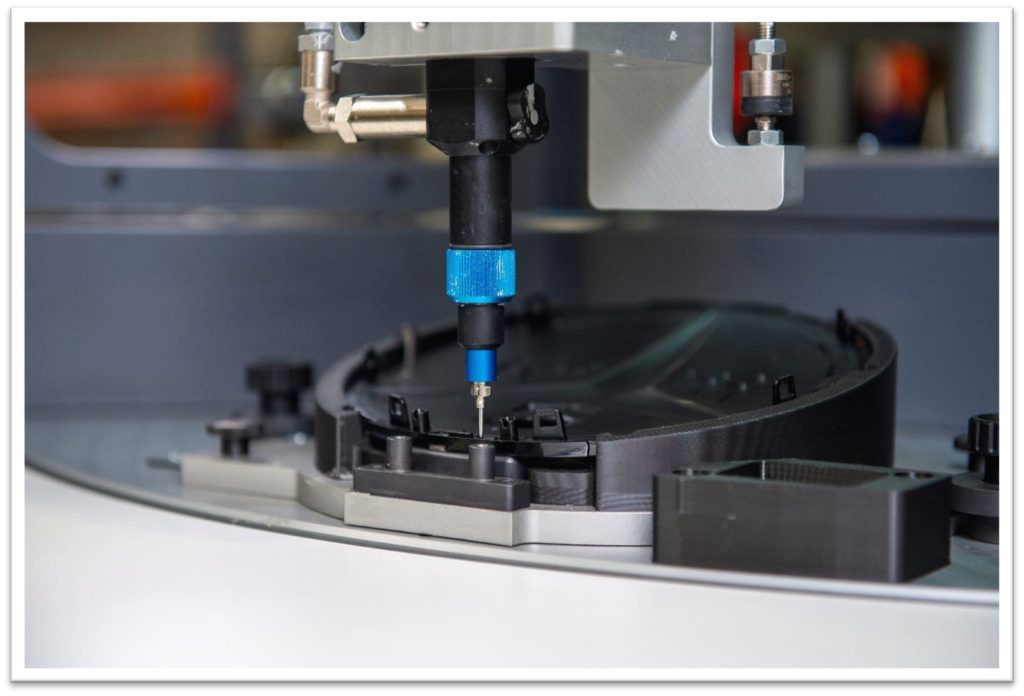

Vision Systems

Vision systems

Our 2D and 3D vision systems guarantee precise quality control for welds, bi-component application, component inspection, and dimensional verification, reducing errors and optimizing production.

Cleaning Systems

Cleaning Systems

We implement ionizing cleaning systems for cleanrooms that remove particles such as fibers, preparing parts for painting or overmolding and ensuring the purity of the components.

Traceability Systems

Traceability Systems

We offer complete traceability solutions with QR code reading, label generation, code marking, and SCADA programming for efficient management of production processes.

Milling Systems

“>Milling Systems

We develop milling systems with controlled aspiration for gray or white environments, reducing waste and dust, ideal for series production with high cleanliness requirements.

Robotics

Robotics

Our robotics improve efficiency and flexibility in processes such as plastic injection, handling, welding, and thread embedding, offering greater precision and repeatability.

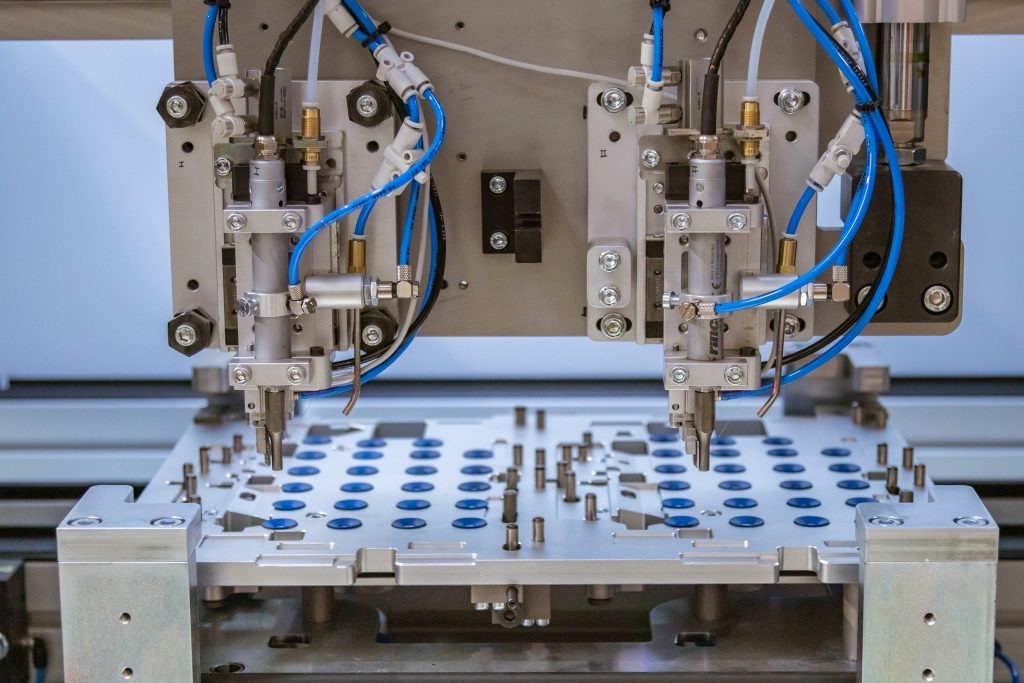

Dispensing Systems

Dispensing Systems

Specialized in component dispensing, our volumetric systems ensure precise supply for UV light or temperature curing processes.

Screwing

Screwing

We implement automatic and manual screwing processes with torque and turn control, ensuring reliable and high-quality unions in final products.

Wire Embedding

Wire Embedding

Our system integrates copper threads into plastic parts for applications such as RFID systems or part heating, expanding design and functionality possibilities.

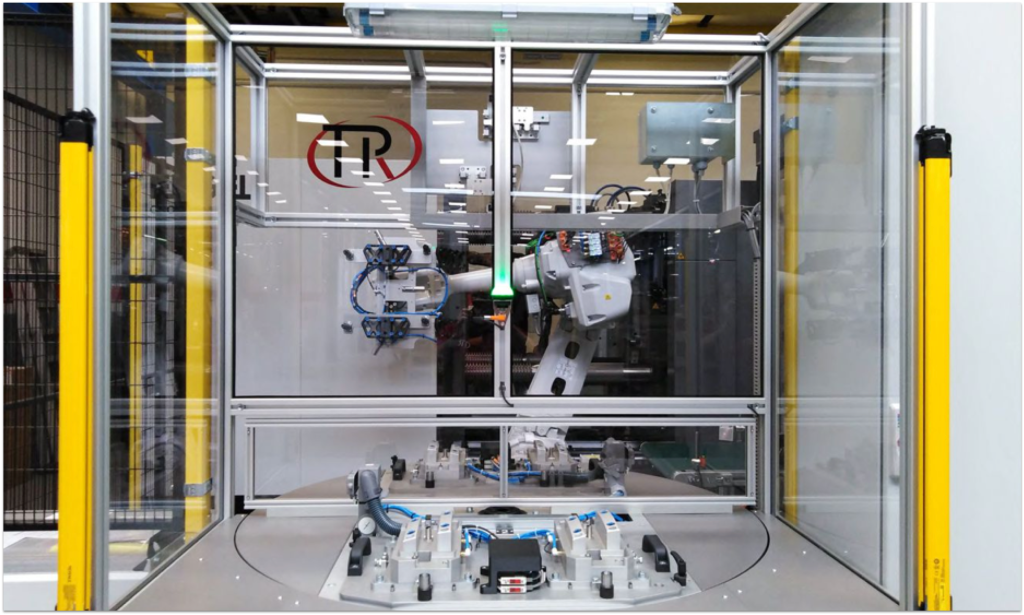

Fully Automated Lines

Fully Automated Lines

We develop fully automated assembly lines that integrate robotics and advanced control systems to optimize production, reduce manual work, and ensure high-quality output for industries like automotive manufacturing.

Tin Soldering

Tin Soldering

Our technology enables precise tin soldering for terminals, wires, and PCBs, ensuring reliable and consistent joints.

Heat Stacking

Heat Stacking

We use automated control for Heat Stacking welding, ensuring reliable and consistent joints in various applications.

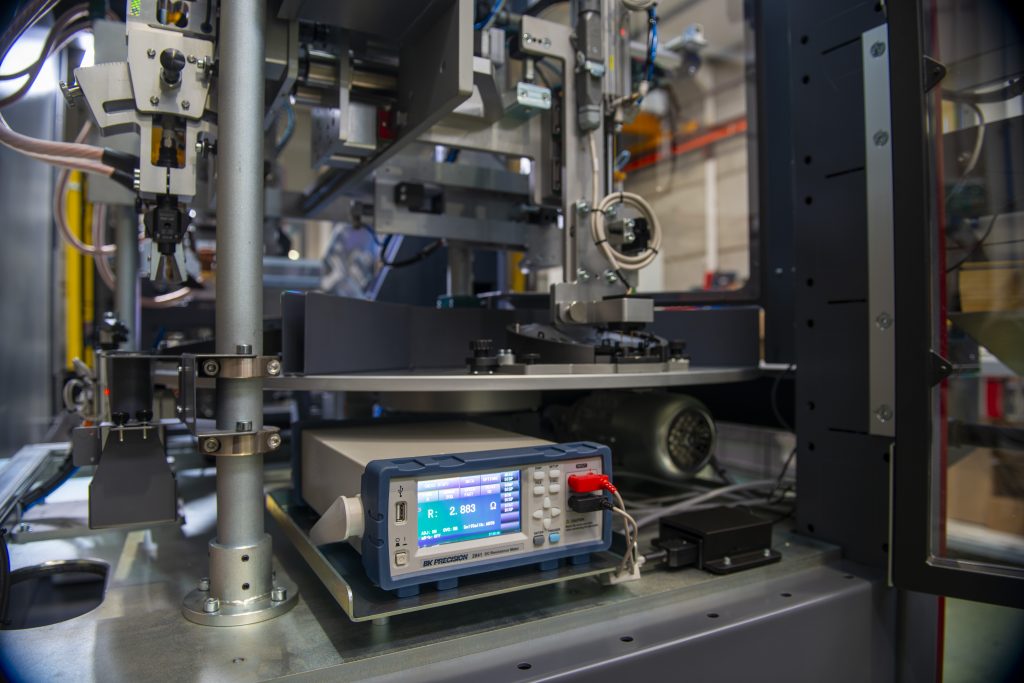

Testing

Testing

We develop advanced testing equipment designed to ensure precision, reliability, and quality control in manufacturing processes, providing accurate results and optimized production.