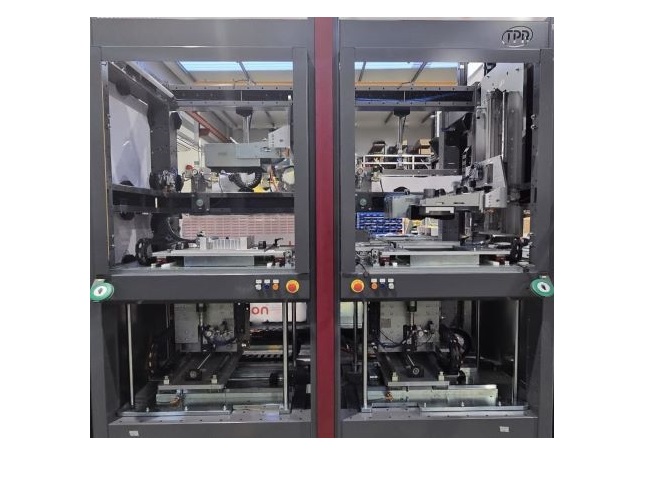

Wire Embedding Line

Challenge

The objective of this automated line is to integrate all the necessary processes for developing this type of product into a single production line. These processes include embedding copper wire, tin soldering, a machine learning-based vision system, resistivity testing, dispensing, and resin curing. The system will also report to the traceability system.

Implemented Solution

We designed and implemented a Wire Embedding Line with the following key features:

- Fully automated line

- Embedding machine

- Soldering machine

- Vision systems

- Resistivity test

- Dispensing and curing

- Traceability system

The machine is capable of achieving a cycle time of 12.5 seconds, depending on the characteristics of the end customer’s piece.

Results

Case of success

- New CNC software development for easy path processing.

- Automatic multimodel changeover with 3 models’ production.

- Deep learning vision system equipped with AI. 96% OEE performance achieved

Keep exploring our case studies!

IMD In Mold Foil Over Injection Cell

This fully automatic line handles the preparation processes for the overinjection of a decorative foil…

Final Assembly Line (EOL)

This fully automated line was designed for flexibility, allowing it to easily adapt to different…

Wire Embedding Line

The objective of this automated line is to integrate all the necessary processes for developing…

Overmolding Cell

Our robotic cells for plastic overmolding machines allow the input of all types of components…

Machine for Soldering and Electrical Testing

The challenge was to design and develop an automated machine capable of assembling and testing…

Milling Machine

The objective was to develop a high-precision milling station for plastic models, capable of maintaining…