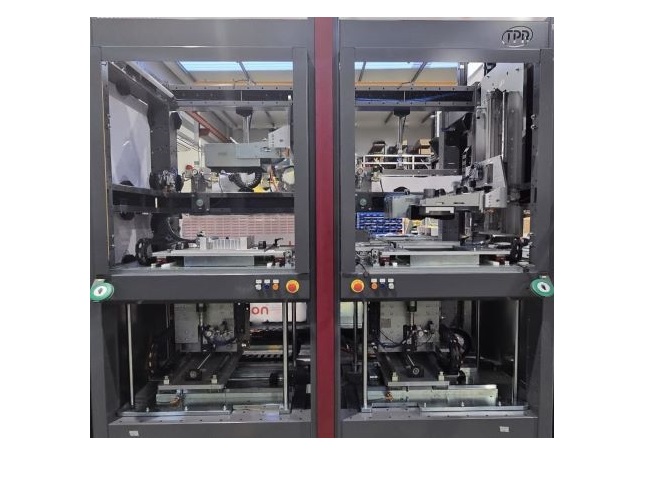

Spot Soldering Station for Terminal Connections

Challenge

The requirement consisted of having the ability to perform tin soldering on various types of cables with different types of terminals. As a result, the machine is being adapted based on the model loaded by the operator, ensuring a highly flexible production process.

Implemented Solution

We designed and implemented a Soldering Station with the following key features:

- Soldering process: 14 adjustable points for tin soldering by Induction system to seal the connection between the cable and the terminal.

- Sliding table to allow working with 1 or 2 operators, providing maximum production flexibility. Automatic and manual processes are performed in parallel.

- Full flexible production: 3 different types of terminals can be loaded at 7 holders depending on the wire model loaded. The machine recognizes the model, and check it with the terminals loaded before adapting the position for soldering process.

- Quick Model Change: A quick model change system with Harting connectors allows for fast and efficient transition between different models.

- Model Parametrization: The system offers model parametrization via a touch screen, enabling easy adjustments for different models and ensuring flexibility in production.

Results

The machine ensures an optimal production process as it offers the flexibility to operate at 30 or 60″ with 1 or 2 operators, while also allowing multiple models to be produced without requiring changeover.

Keep exploring our case studies!

IMD In Mold Foil Over Injection Cell

This fully automatic line handles the preparation processes for the overinjection of a decorative foil…

Final Assembly Line (EOL)

This fully automated line was designed for flexibility, allowing it to easily adapt to different…

Wire Embedding Line

The objective of this automated line is to integrate all the necessary processes for developing…

Overmolding Cell

Our robotic cells for plastic overmolding machines allow the input of all types of components…

Machine for Soldering and Electrical Testing

The challenge was to design and develop an automated machine capable of assembling and testing…

Milling Machine

The objective was to develop a high-precision milling station for plastic models, capable of maintaining…