Milling Machine

Challenge

The objective was to develop a high-precision milling station for plastic models, capable of maintaining fast production cycles while ensuring clean and accurate cuts. The solution required efficient handling of models, precise milling capabilities, and automated cleaning to maintain quality.

Implemented Solution

We designed and implemented a milling station with the following key features:

- High-Speed Milling Head: The milling head operates at 60,000 rpm, ensuring precise and efficient cutting of plastic components.

- Feed Rate: The milling head moves at a speed of 40 mm/s, optimizing both speed and accuracy during the milling process.

- Industrial Suction Cleaner: To maintain a clean working environment and ensure high-quality finishes, an industrial suction system is integrated to remove plastic cuttings as they are produced.

- Plastic Part Milling: The machine is specifically designed for cutting and shaping plastic parts, ensuring reliable performance for this material.

- Quick Model Change: A quick model change system with Harting connectors allows for fast and efficient transition between different models.

- Model Set up: Based on internal developed software, a dxf file can be loaded to recognize the path to cut and transform to Gcode file to control the servos of the CNC. The system offers model parametrization via a touch screen, enabling easy adjustments for the shape of the different models and ensuring flexibility in production.

The station delivers efficient operation with precise control over the milling process, maximizing productivity and quality.

Results

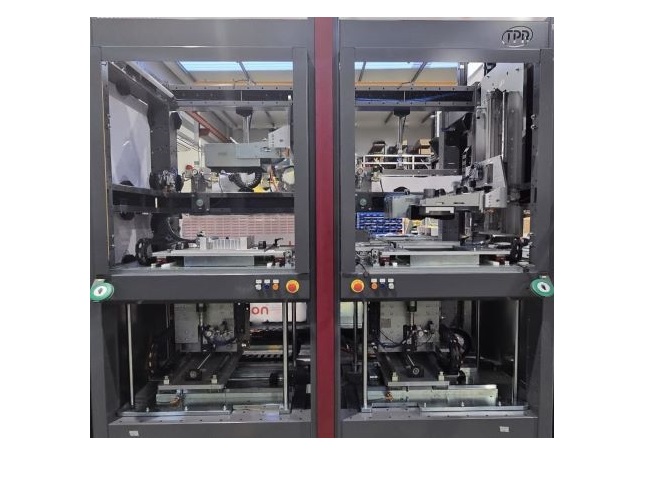

Our solutions for milling have different options of machines:

- Single 3 axis XYZ milling machine

- Double 3 axis XYZ milling machine

- Single 5 axis XYZ milling machine with 1 gripper. Capable to rotate the tool for different draft angle and the gripper to perform the full contour shape at once.

Keep exploring our case studies!

IMD In Mold Foil Over Injection Cell

This fully automatic line handles the preparation processes for the overinjection of a decorative foil…

Final Assembly Line (EOL)

This fully automated line was designed for flexibility, allowing it to easily adapt to different…

Wire Embedding Line

The objective of this automated line is to integrate all the necessary processes for developing…

Overmolding Cell

Our robotic cells for plastic overmolding machines allow the input of all types of components…

Machine for Soldering and Electrical Testing

The challenge was to design and develop an automated machine capable of assembling and testing…

Milling Machine

The objective was to develop a high-precision milling station for plastic models, capable of maintaining…